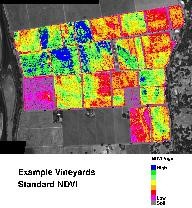

| Profit Improvement A recent study from Australia describes the financial advantage of using NDVI imagery on a 8.15 acre site to determine a differential harvesting program. Briefly, the study stated that normal harvesting resulted in returns (based upon retail bottle price of $19.00) of $544,065. Using NDVI imagery to divide the blocks into high quality ($30.00/bottle) and lower quality sections ($19.00/bottle), then harvesting deferentially brought returns totaling $648,675 — an increase of return of $104,610, or $12,835 an acre! With the cost of the imagery at $10.00 an acre in Australia that was a return on the imagery of 1200% and an increase in revenue for the project of 19% overall.(1) |

||||

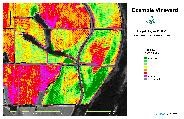

| Problem Identification – Problems causing non-uniformity in a vineyard are quickly recognized and the extent described with an NDVI image. A plan of field examination can be readily developed and implemented to determine if the problems are pest, nutritional, water or disease. If the NDVI image is georeferenced in digital form, it can be loaded on a PDA with GPS to immediately locate the required sample areas. |

|

|||

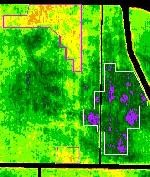

| Practice Improvement – A key objective of vineyard management is to improve the return-on-assets through improving fruit quality (i.e., higher value fruit) while at the same time bringing the vineyard to as close to uniform as possible. Simple statement, tough job! A. Sample zones for petiole analysis can be determined from NDVI as petiole pressures match well with NDVI classes. B. Time period comparisons can describe the progress of changes to bring about uniformity and to statistically describe uniformity. C. Differences in vegetation growth on NDVIs help design soils analysis plans for existing and planned vineyards. D. Irrigation sets and block changes are typically the first benefit of NDVI imagery with either savings in water or increases in water distribution efficiency. |

||||

|

Precision Application – Fertilization and application zones are easily described from NDVI imagery and the vineyard can be staked for start-stop points or field computers can be carried by applicators with specified GPS points. Differential mowing and disking is easily described in the same manner. How much would your vineyard save annually with better application control? | |||

|

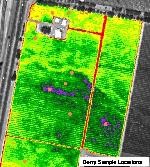

Berry Quality Sampling – The NDVI image is an excellent tool to design quality sampling zones based upon the NDVI classifications. The winemaker will quickly determine differences between NDVI color classes in terms of sugar levels, taste qualities, cluster size, etc. The color classes will then give a good estimate of fruit distribution within each class. Again, gps handheld PDAs, or similar computers, can speed the process for the winemaker in reaching appropriate sample sites. | ||||

| Harvest Planning – While an idealized goal of management is to provide uniform vineyard blocks, the reality is it takes time, and some blocks will just never be uniform. The winemaker can use an NDVI image, once sugar and other qualities have been related to color classes by block, to define a harvest plan. The vineyard can be flagged, staked or otherwise marked to define harvest zones. Another significant benefit to the winemaker as a result of using NDVI is the ability to easily view the vineyard on a sub-block basis. This allows the winemaker to create a greater number of wine lots with greater uniformity in each lot, which in turn allows for more blending and a greater potential return to the winery. |

|

||||

|

Properly utilized by the vineyard manager and winemaker, NDVI imagery will:

Ø Leverage the return on vineyard assets through increased efficiency Ø Improve vineyard management protocols Ø Improve grape quality Ø Increase block uniformity Ø Allow the winemaker to view block production and quality at the sub-block level Ø Increase efficiency in berry sampling Ø Improve harvest design efficiency Ø Provide an excellent grower relations tool Ø Expand the number of wine lots while improving the quality and uniformity of the lots, which in turn allows for more blending options and higher potential returns on the finished product. |

|||

|

||||

Wine Grapes, India

The quality of wine grapes is determined largely by when they’re harvested—picking them at the exact right time for sugar content. Using Agribotix software, a grower in India can schedule harvests for specific plots rather than all at once, achieving higher revenues at lower cost.